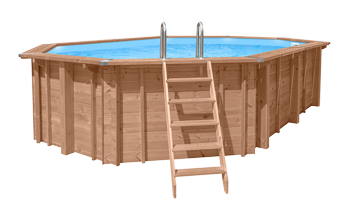

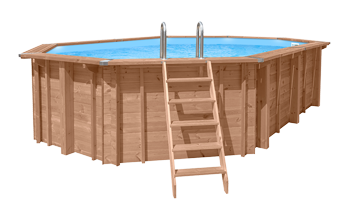

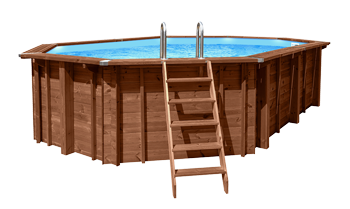

Wood from Scandinavian forests comes with unique properties. Harsh climate shapes growth rings in pine trees noticeably denser than anywhere else, which makes pine timber much stronger and long-lasting. Even unimpregnated heartwood is resistant to weathering.

Wooden pools. Meet the Luxury that Was Born in the Forest.

An old gossip says that the first wooden pool was made by Canadian woodchoppers, seeking a place to cool down after the whole day of hard work in the heat. We are all very grateful for their invention, especially on sunny days!

Made of Scandinavian Timber

We take care that all pools made of this unique timber will last even longer. Before becoming a high-quality Abatec swimming pools, all wood planks undergo multi-stage processing, which includes seasoning, drying and impregnation.

Product delivery

Product delivery

Product delivery

Product delivery