Wood treatment is an essential practice that extends the longevity and enhances the aesthetics of wooden structures. Whether you’re a seasoned woodworker or a DIY enthusiast, understanding the ins and outs of wood treatment can be invaluable. This comprehensive guide covers everything from basic concepts to advanced techniques.

Understanding Wood Treatment

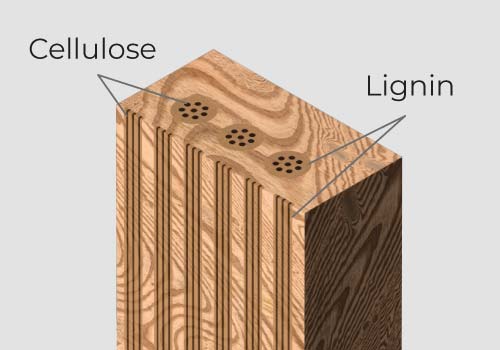

The science behind wood treatment lies in understanding the structure and properties of wood. Wood is a natural, hygroscopic material composed of cellulose fibers bound together by a material called lignin. When wood is exposed to water, it swells as the cellulose fibers absorb the water. Wood easily absorbs water and becomes a breeding ground for insects and fungi.

Wood treatment involves the application of various techniques and substances to protect wood from environmental factors such as weather, UV radiation, moisture, insects, fungi, and potential physical damage. It increases its durability and overall lifespan. This is often essential for outdoor structures, where wood is especially exposed to harsh weather conditions and destructive organisms.

Key Goals of Wood Treatment

Durability and Longevity

By protecting against insects, rot, and decay, treatments can significantly extend the useful life of the wood.

Reduce Water Absorption

By either sealing the wood’s surface or altering its internal structure.

Dimensional Stability

Certain treatments aim to reduce the wood’s tendency to warp, swell, and shrink in response to changes in humidity and temperature.

Improved Strength

Some treatments can increase the strength of the wood, making it more suitable for certain structural applications.

Aesthetics

Some treatments can enhance the appearance of the wood, such as stains that change its color or oils that bring out its natural grain.

Resistance to Ultraviolet (UV) Light

Certain finishes can help protect the wood from the damaging effects of the sun’s UV rays, which can cause the wood to grey and weaken over time.

Treatment Methods

Pressure Treatment

The most common methods of wood treatment involve the application of chemical preservatives. These chemicals are introduced into the wood’s structure via a process known as pressure treatment. The treatment usually takes place in a special autoclave at a manufacturing facility. Main goal is to protect wood from insects and fungi, but also to increase its strength and stability.

The process generally proceeds in this way:

- Chemical preservatives are prepared for application on the wood

- The wood is placed in a sealed autoclave

- A vacuum is created within the autoclave

- An impregnating agent is introduced into the wood cells

- A salt solution is pressure-injected into the wood

- The excess liquid is drained off

- The wood undergoes impregnation fixation in a well-ventilated, covered area.

While pressure treatment offers many benefits, it is not absolute. Additional protection is still necessary to protect wood. Regular maintenance plays a crucial role in ensuring its longevity. That’s where manual oil treatment comes in place.

Manual Oil Treatment

Manual oil treatment for wood involves the application of a protective oil on the wood’s surface.

This protective oil guards the wood against moisture, thus reduces the possibility of the wood cracking and warping and enhances the natural beauty of the wood, often bringing out the grain and deepening the color. Some oil-based products contain also special additives that protect the wood from damage caused by UV rays. These UV blockers or absorbers can prevent the wood from graying or fading over time due to sun exposure.

The process is typically done by applying the oil onto the wood and then wiping off the excess, allowing the wood to soak in the oil. It’s essential to note that different types of oil offer varying levels of protection and aesthetic enhancement, and the choice of oil can be influenced by the type of wood, the desired finish, and the wood’s intended use.

Regular reapplication of the oil is crucial to maintain the wood’s appearance and protective qualities, as the oil can wear off over time or be washed away by rain or cleaning processes. The frequency of reapplication can depend on the specific oil used and the environmental conditions the wood is exposed to. At Abatec we recommend to carry it out at least once a year.

Treating Wood Step-by-Step (DIY)

Treating wood is a process that requires some preparation and patience. Here are the basic steps:

Preparation

Start by cleaning the wood to remove any dirt or grime. This will ensure that the treatment adheres properly to the wood’s surface.

Selection

Choose the right treatment based on the wood’s intended use and your desired finish. For the optimal maintenance of wooden swimming pools, we strongly recommend using high-quality Natural Woodstain Oil.

Application

Apply the treatment according to the manufacturer’s instructions. This often involves brushing or spraying the treatment onto the wood, then allowing it to dry.

Maintenance

Once treated, wood requires regular maintenance to keep it in good condition. This might involve reapplying the treatment every year or cleaning the wood regularly to prevent buildup of dirt and grime.

Maintaining and Preserving Treated Wood

Proper maintenance is key to preserving treated wood. Regular cleaning and periodic reapplication of the treatment can greatly extend the lifespan of your wood. It’s also important to promptly address any signs of damage or decay, as these can quickly spread if left untreated.

Advanced Wood Treatment Techniques and Their Applications

As you become more experienced with wood treatment, you might want to explore advanced techniques. These can offer improved results or unique finishes that can enhance the aesthetics of your wood. For example, you could experiment with wood staining, which can introduce different colors or effects.

Advanced techniques that you might want to consider:

Tung Oil

Tung oil is a natural finish that has been used for thousands of years. It creates a beautiful, rugged, and highly water-resistant coating on wood and other porous surfaces. The application process can take some time, but the result is a non-toxic, water-resistant, and anti-mildew finish that’s easy to clean.

Linseed Oil

Boiled linseed oil is another excellent choice for coating wood surfaces and preventing water damage. Unlike other methods, it requires no special surface prep. Raw linseed oil can take weeks to dry thoroughly, making it impractical for some projects. In contrast, polymerized versions of linseed oil dry faster and show less yellowing.

Danish Oil

Danish oil is a blend of tung oil with resins and solvents, offering an excellent finish for most wood types. It penetrates deep into the timber, offering a durable, natural, water-resistant, low-sheen finish. For outdoor furniture, it is recommended to reapply Danish oil every two years to prevent damage and protect the woodwork against sun and moisture.

Wipe-On Oil

Wipe-on oil finishes are easy to apply and can protect your wood against water, household chemicals, food stains, and wear. They can be applied easily with a brush or cloth and come in many varieties, including oils, waxes, urethanes, and combined products.

Common Mistakes in Wood Treatment and How to Avoid Them

As with any skill, there are common mistakes that people make when treating wood.

Mistakes to be aware of

Improper Preparation

The first step in any wood treatment process is to properly prepare the wood. This includes cleaning the wood and ensuring that it’s dry before applying any treatments.

Choosing the Wrong Treatment

The right treatment depends on the type of wood and its intended use. Indoor wood treatment differs from outdoor wood treatment. Outdoor wood is exposed to environmental elements and needs treatments that protect against moisture, temperature changes, sunlight, and insects. At Abatec, we advocate for the use of premium Natural Woodstain Oil, offering unmatched protection and longevity to our products, ensuring their optimal performance and aesthetic appeal.

Rushing the Process

Some treatments, like tung oil, require time to dry between coats. Rushing this process can lead to wrinkles that must be sanded off later.

Inadequate Maintenance

Maintaining treated wood properly is crucial to keeping it in good condition. The frequency of maintenance can depend on several factors, including the specific treatment or oil used and the environmental conditions the wood is exposed to. For instance, at Abatec, we recommend reapplying the treatment at least once a year to ensure optimal protection. Also remember about regular cleaning of the wood to prevent the buildup of dirt and grime.

Conclusion

Understanding the nuances of wood treatment can seem overwhelming at first, but with knowledge and practice, you’ll be able to extend the life and enhance the beauty of your wooden projects. Make sure to follow manufacturer’s guidelines, and if you’re ever unsure, don’t hesitate to ask a professional for advice.

Want to learn more about wood?

Click here